Setting Float Valve Height Carburettor

To properly tune the Stromberg, one must have the Stromberg adjusting tool (a 1/8' allen wrench within a pinned tube), a 10mm long open end wrench, a small screwdriver, and a medium screwdriver. A tach/dwell is always most helpful.

The engine is started from cold, and the spring loaded idle screw is adjusted until the engine is running at 1800 rpms maximum. Open eps file in gimp. One the engine has fully heated and the engine dropped to its lowest rpm (choke all the way off), then the locknut screw (hence the 10mm wrench) is adjusted until the engine is idling at about 850-900 rpms. All further adjustments to idle speed will be made again with the spring loaded screw.

Now the mixture is adjusted. Lift the air piston ever so slightly and judge the change in rpm. If the idle speed continues to rise as the piston is lifted, the mixture is too rich. Turn the allen wrench anti clockwise to lean it out. If, on the other hand, the idle speed slows or stumbles when the piston is slightly lifted, then the mixture is too lean. Turn the allen wrench clockwise to richen it. A proper idle mixture allows the rpm of the engine to rise and steady, or rise and slowly fall off as the piston is slightly lifted. As the correct mixture is reached, the idle speed will rise, and several adjustments may be necessary to hold the idle at that 850-900 figure. Be certain to rev up the engine, to clear it out, between each adjustment.

When adjusting the carb at home, tighten the air bleed screw (MGB) so that no air passes through this circuit.

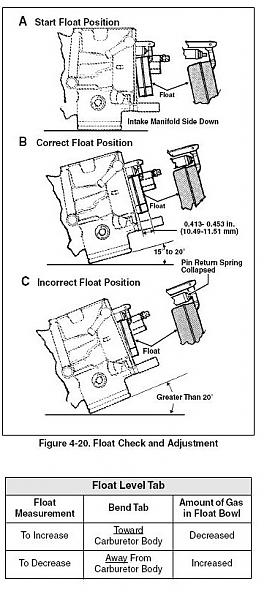

Setting the float height on Dellorto carburetors Detailed technical information regarding Dellorto motorcycle carburetors, how to tune Dellorto motorcycle carburetors, Dellorto parts diagrams, slide specifications, needle specifications, jet specifications, and atomizer specifications. Updated: 2009 April 29. View more topics related to. The Float Needle The float needle, which moves within the seat, acts as a valve that either allows or stops the flow of fuel into the float bowl. Mikuni uses two types of needles. One needle is a corrosion-resistant steel alloy, the other has a Viton rubber coating over the tip of a steel needle.